DUST HAZARD ANALYSIS OVERVIEW AND SERVICES

A dust hazard analysis (DHA) is a mandated formal review of the potential for combustible dust explosions required for all sites that generate, store or handle combustible dusts.

The requirement to perform a DHA for all such facilities was established in 2015 in NFPA 652 – Standard on the Fundamentals of Combustible Dusts – and is enforced by OSHA.

Combustible dust explosions are one of the leading causes of multi-fatality incidents in industry.

ADF Serves the following industries

Cornmeal

Oil seed

Confectionaries

Bakeries

Wood

Cemet

Animal Feed

Distilleries

Pet Foods

Key Takeaways:

- A Dust Hazard Analysis is a document describing fire and explosion hazards related to combustible dust and outlines an implementation plan to correct any issues discovered at the inspected facility.

- A DHA is required for all facilities that generate, handle, or store combustible dusts.

- ADF can perform the DHA, provide dust combustibility testing, and follow up with designs to implement combustible dust mitigation solutions.

What Is A Dust Hazard Analysis?

A dust hazard analysis (DHA) is a document that describes the fire and explosion hazards associated with combustible dusts throughout a facility and provides an implementation plan to correct deficiencies in hazard protection.

Conducting a dust hazard analysis is an important aspect of dust safety and process safety. By conducting a hazard analysis, employers can assess the workplace for potential dust hazards and implement measures to control exposures and minimize risk.

This is part of an overall safety management system for combustible dusts and helps to ensure the health and safety of employees.

All facilities that generate, handle, or store combustible dusts are required to complete and maintain a DHA. For new facilities, a DHA may be required by the local Fire Marshal to obtain an operating permit and insurance providers may also enforce this requirement.

Above: Matt Williamson’s recent presentation on combustible dust compliance with evolving regulations

Understanding Dust Safety And Explosion Prevention

Combustible dust explosions occur in manufacturing facilities when finely divided solid particles that are capable of burning rapidly, become suspended in air and ignite.

The explosion is caused by a mixture of the dust, air, and an ignition source such as a spark or a hot surface. The dust particles can come from a variety of materials such as wood, coal, flour, sugar, and metal, among others.

If the dust accumulates on surfaces or in the air, the buildup of the dust increases the risk of explosion.

Combustible dust explosions have resulted in many catastrophic incidents and multiple fatalities across a variety of industries.

An industrial combustible dust explosion occurs once every three days on average. These events can be prevented by mitigation of one of the five criteria for a dust explosion to occur – fuel source (dust), ignition source, oxygen, dispersion, and containment. Often, these mitigating solutions are simple. Additionally, many new technologies are available to reliably suppress or disrupt an explosion.

To prevent these incidents, it is important to implement proper dust control measures, including regular cleaning, adequate ventilation, and the use of explosion-proof equipment.

Does OSHA Require A Dust Hazard Analysis?

OSHA often cites NFPA 652 as a means to comply with its regulations, and this suggests that OSHA views NFPA codes as the standard, while allowing facilities to assess their combustible dust risk using alternative methods.

The National Fire Protection Association (NFPA) codes and standards for combustible dust and fire and explosion safety are often used as legal requirements for building codes, by insurance companies, and other organizations.

By learning about the requirements set by the NFPA, facilities can ensure they are in compliance with the latest standards for combustible dust and process hazard management.

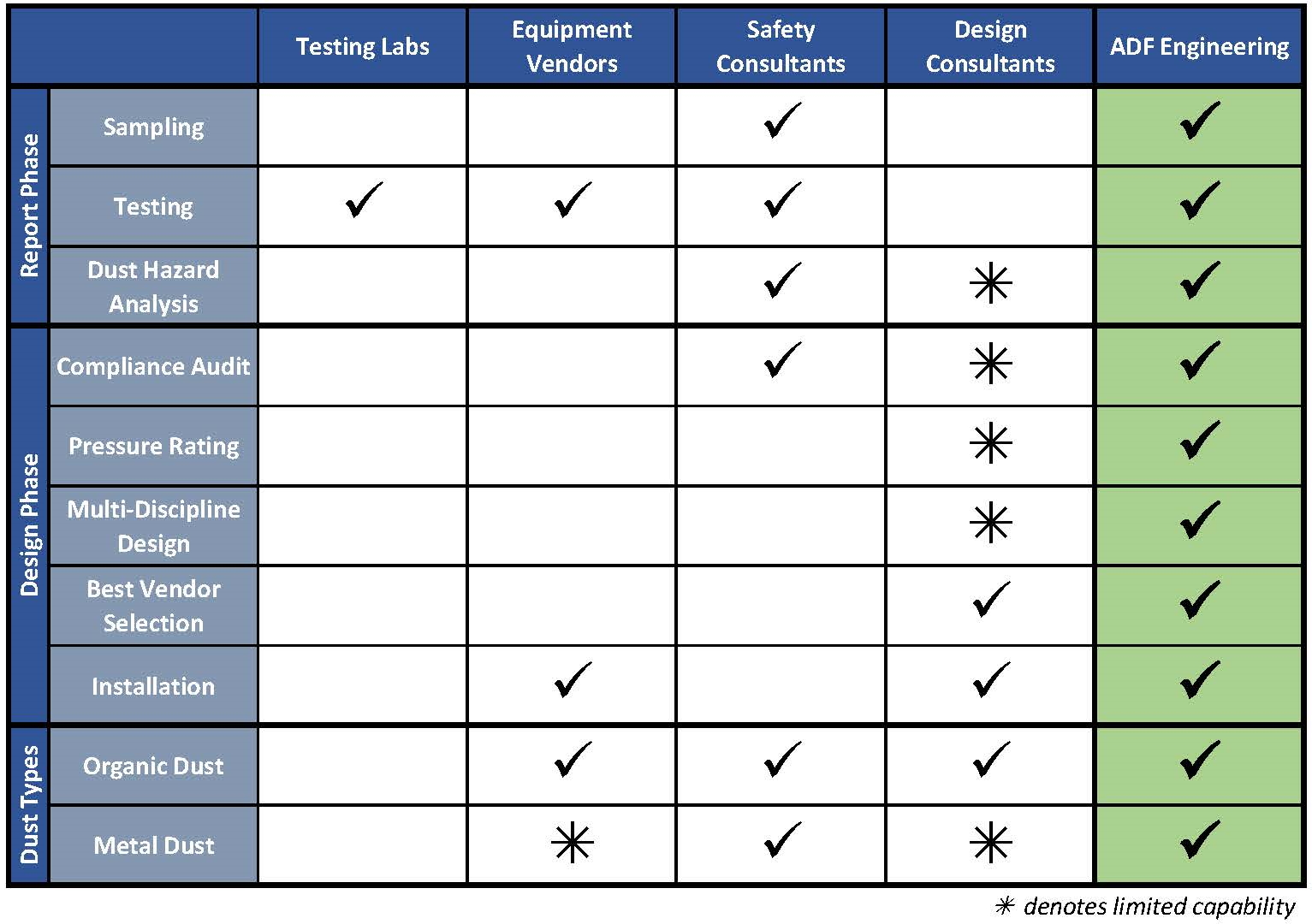

What To Look For In A Dust Hazard Analysis Consultant

A DHA consultant must be experienced. ADF has conducted nearly 100 DHA’s since 2016 in a wide variety of industries, including food ingredients, animal feed, oilseeds, metal powders, plastic dusts and saw dust.

The ADF Approach To Dust Hazard Analysis (DHA)

ADF goes beyond the DHA report to offer technical solutions to the recommended site improvements. ADF can provide combustibility testing to generate combustibility data for the site prior to development of the DHA report. ADF is the complete combustible dust solution provider, from investigation through implementation.

WHAT IS INCLUDED IN OUR DHA

Combustibility Testing

ADF partners with a qualified national lab to provide the required combustibility data – Kst, Pmax, MEC, MIE and MIT

DHA Review

ADF facilitates a DHA review with site personnel and generates the DHA report including specific recommendations and prioritization to address findings.

Implementation Plan

ADF assists with development of an implementation plan with specific action items and can design modifications to meet code compliance and address any gaps in dust hazard mitigation.

What Does A DHA Cost?

While each DHA will be tailored to your specific needs and plant conditions, these ranges could be representative of what to expect:

- Small Facilities: A small-scale production with only one or two dusts and requiring minimal facility upgrades. $5,000-$15,000

- Mid-Sized Facilities: Processing facility that handles multiple dusts. $10,000-$20,000

- Large-Scale Facilities: A complex facility handling multiple dusts in multiple processes. $15,000+

How To Stay NFPA 652 Compliant

Staying compliant with NFPA 652 requires regular updates to your dust hazard analysis (DHA) to ensure continued safety.

Once DHA findings have been addressed, the DHA must be updated every 5 years. Furthermore, any changes made to the process or dusts handled requires a formal Management of Change process to update the DHA.

The dust hazard analysis is critical in determining the risk of combustible dusts and evaluating process hazards, which involves analyzing dust samples and performing required testing to determine the combustibility of the solids.

The results of the DHA provide the necessary information for making upgrades to the facility and process systems to mitigate the risk of dust-related incidents.

It is important for facilities to regularly assess the risk of dust hazards and learn from industry news to stay current on the latest developments in dust safety and hazard management. By using a specialized DHA consultant like ADF Engineering, and maintaining a comprehensive approach to process safety, facilities can ensure they are providing a safe plant environment and meeting the required standards set forth by the NFPA.

Learn more about bulk and powder material handling offering from ADF

Interested in learning more about our DHA services?

Please fill out the form below to start a conversation with our team about how we can evaluate your facility for combustible dust hazards.